-

Huayou and Tianjin B&M have both been selected as one of the "Top 100 Enterprises in Electronic Information Competitiveness"!

2024-08-16 -

Building a Global Path | Huayou and Hyundai Glovis Build a New Pattern of Battery Recycling Industry Chain

2024-08-16 -

Successful Launch of Huayou Cobalt CDM Social Responsibility Project in DRC

2024-08-07

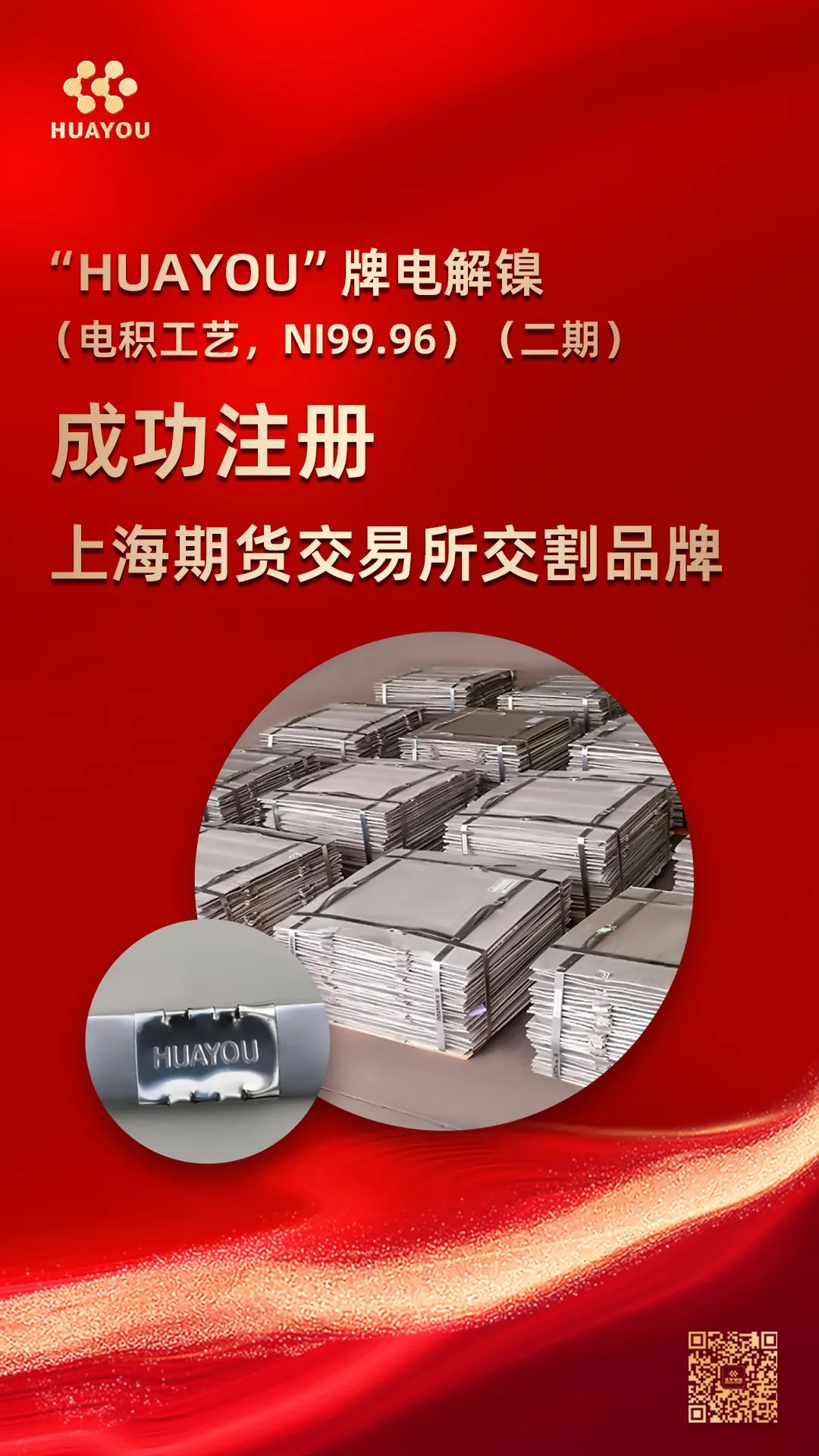

“HUAYOU” Brand Nickel Cathodes Successfully Registered Again!

-

2024-06-27

-

Page views:551

On 17th June, "HUAYOU" brand nickel cathodes (electrodeposited technology, Ni99.96) (Phase II) produced by Huayou Cobalt's subsidiary Quzhou Huayou Cobalt New Materials Co., Ltd. was successfully registered as the delivery brand of nickel futures standard contract of Shanghai Futures Exchange (hereinafter referred to as "SFE"), with a registered production capacity of 30,000 tonnes. In June 2023, "HUAYOU" brand nickel cathodes (Phase I) was successfully registered with a capacity of 6,000 tonnes, which is a five-fold increase in the quantity of nickel cathodes delivered in just one year, and it will cope with the liquidity risk of the market to a greater extent and improve the Company's operation.

Shanghai Futures Exchange (SFE) is one of the four most authoritative exchanges in China, and the registration of delivery brands has strict requirements on product quality, enterprise management and product market recognition. SFE has highly available and high-performance computer trading, settlement, wind control and other systems, and ensures the real-time efficiency, safety and reliability of remote trading through large-capacity optical fibre, dedicated data lines and other means of communication. SFE adheres to the responsibility of serving the real economy and provides solid support for the successful registration of "HUAYOU" brand.

"Since January 2024, the company has been actively communicating with Shanghai Futures Exchange, and after rigorous on-site inspection and sample testing, finally, Shanghai Futures Exchange recognised that "HUAYOU" brand nickel cathodes (Phase II) produced by Huayou Cobalt complies with the requirements of the delivery brand, and is allowed to become the delivery brand, and the nickel cathodes with "HUAYOU" logo will be in the hearts of the customers again from now on.

The nickel cathodes process of "HUAYOU" brand adopts the joint oxygen pressure and high-efficiency circulating leaching MHP process independently researched and developed by HUAYOU Cobalt, which has three major advantages, such as low carbon and green, short-range integration, and automatic and high efficiency, The products have the characteristics of high purity, low impurity, high solubility, anti-corrosion, etc., and are widely used in high-temperature alloy fields such as aerospace, automobile, seawater desalination, petroleum, chemical industry, shipbuilding, medical materials, etc., as well as in electroplating market of high-end electronic and electronic components.

As the world's leading enterprise in the integration of green manufacturing of new energy lithium materials, Huayou Cobalt has always been adhering to the business essence of "customer-centered, creating value for customers", and has been striving to build a new energy lithium industry chain from nickel-cobalt-lithium resource development, green refining of non-ferrous metals, to the deep processing of lithium anode materials, and then to the recycling and reuse of resources. Huayou is market oriented and technology oriented, and is committed to original basic R&D, product R&D, and equipment R&D, and is constantly pioneering and innovating, so as to contribute to the high-quality development of the enterprise and the industry.

-

Southeast/South/East China Business Department, New Energy Marketing Centre

Ternary Cathode Materials Industry (Domestic Markets)

-

Japan& Korea Business Department, New Energy Marketing Center

Ternary Cathode Materials Industry (Japanese &Korean Markets)

-

European& American Business Department, New Energy Marketing Center

Ternary Cathode Materials Industry (European& American Markets)

-

Operation Department, Recycling Industry Group

Domestic Waste Power Battery and Material Recycling Industry